Trumpf, Schott and Bosch involved in project ScULPT to produce new source for with tenfold increase in productivity for materials processing.

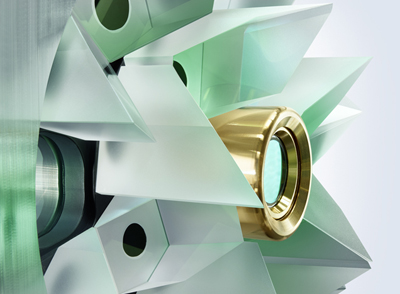

YAG disk generates multi-kilowatt laser output.

Industrial laser giant Trumpf has announced its leadership of a new joint research project, intended to create what it calls “the ultra-short pulse laser of the future”.

The project named “Scaling Ultrafast Laser Productive Precision Processing Technology” – ScULPT – was set up by partners from science and industry with the aim of developing an efficient, powerful, ultra-short pulsed laser system for machining different types of glass and metals with a tenfold increase in throughput.

Dr. Dirk Sutter, head of ultra-short pulse laser development at Trumpf and coordinating the research activities, explained, “Our goal is to drastically reduce the processing cost per part in order to make new applications economically viable.”

To enable this breakthrough, a significant increase of the output power available from industrial grade ultra-short pulse lasers, such as Trumpf’s TruMicro series is required.

High precision

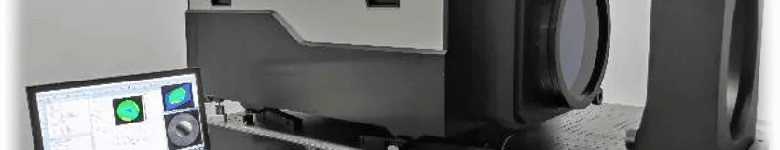

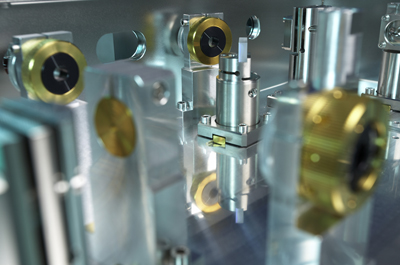

A view inside an ultra-short pulse laser from Trumpf’s TruMicro range.

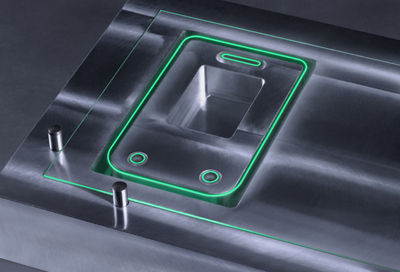

With their high pulse peak powers of several gigawatts and extremely short pulse durations, ultra-short pulse lasers are ideal tools for high-precision machining of many materials including, for example, the high-strength cover glasses used for optical displays.

However, nowadays the volume of material that can be modified or removed with each laser pulse – and therefore the resulting process throughput – is limited by the available laser pulse energy. This limitation sets the starting point for the new ScULPT project where the partners will be aiming to accelerate process throughput at least proportionally in relation to the increase in laser power.

New beam sources aside, transforming increased laser power into faster machining processes requires additional developments which also form part of the ScULPT project. These include the construction of application-specific machining modules with suitable, fiber-based beam guidance and beam shape adaptations for individual processes, as well as optimized synchronization between laser and beam scanning systems.

Display manufacturing with a TruMicro ultra-short pulse laser.

Entire value chain

The ScULPT project team is formed by several major German engineering companies: Trumpf, Schott and Bosch; as well as the Universities of Jena (Institute for Applied Physics) and Stuttgart (Institut f