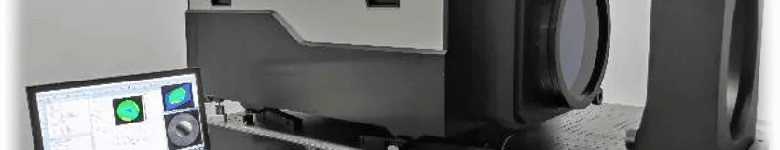

The Fraunhofer Institute for Photonic Microsystems (IPMS), Dresden, Germany, has previously presented a mobile MEMS scanning grating spectrometer in “sugar cube” format at Photonics West; the spectrometer is used to study gases, liquids and solids by analyzing light in the near infrared range (950nm to 1900nm).

At this year's Photonics West trade show, the scientists will introduce a novel approach that also uses MEMS technology for spectral analysis in the medium infrared range (3 – 12 µm). In this region many chemical substances that are important for security monitoring purposes feature unique and characteristic absorption lines. Thus different hazardous materials can be quickly detected and quantified using a compact mobile sensor system.

Environmental contamination, industrial accidents or terror attacks: there are many types of events that can put the health of humans and the environment at risk due to the leakage of hazardous substances. The assessment of and timely response to possible risks requires that the type and concentration of potentially hazardous substances can be qualitatively and quantitatively determined as quickly as possible.

Spectroscopy is ideal for this purpose because the measurement process is a non-contact procedure, which can be applied to many different solid, liquid or gas-shaped materials as each molecule has its own characteristic infrared spectrum. The challenge for researchers is to intergate this measurement technology in a robust and compact design, and enable it to cover the largest possible wavelength range in the key medium infrared range.

To achieve this, Fraunhofer IPMS and 17 other project partners from nine countries are working on the development of a novel, handy variable frequency monochromatic light source for the medium infrared range as part of the European joint venture research project known as MIRIFISENS – Mid Infrared Innovative Lasers for Improved Sensor of Hazardous Substances. It forms the technological basis for the development of handy spectrometers for rapid detection of the concentration of different hazardous materials in situ.

Technology

The heart of the system consists of a miniaturized quantum cascade laser (QCL), which is being developed by researchers of the Fraunhofer Institute for Applied Solid State Physics (IAF) in Freiburg. The QCL covers a large range of the wavelengths that are important for the spectroscopic »fingerprint« in the medium infrared range.

To tune the QCL to the desired wavelengths, scientists at Fraunhofer IPMS developed a highly reflective diffraction grating with a diameter of 5mm as well as the associated control electronics. The micro-mechanically manufactured diffraction grating acts as the quantum cascade laser's variable frequency external resonator. It allows for the tuning of laser wavelengths with a frequency of 1kHz, with a variable frequency range of up to 20 percent of the central wavelength. By this means, the sample can be irradiated with different wavelengths in the time multiplex, and conclusions can be drawn with regard to the type and concentration of the hazardous materials using the “fingerprint”.

Fraunhofer IPMS' project Manager Dr. Jan Grahmann explained the benefits of MEMS technology thus: “Electrostatically-driven MEMS grating mirrors are much more compact than galvanometer scanners, make almost no sound and allow for very high scanning frequencies due to their low weight. In combination with miniaturized laser sources, they are ideal for integration into mobile handy sensor systems, simple measurements on location and for integration into industrial measurement technology at production and processing facilities.”

At the Photonics West in San Francisco (February 7–12, 2015), Grahmann will present this technology to a scientific community on February 12, as part of a wider presentation entitled “Large MOEMS diffraction grating results providing an EC-QCL wavelength scan of percent”. Attendees will also have an opportunity to view the possibilities of miniaturization using MEMS Scanning Grating Technology at the Fraunhofer IPMS' stand 4409 in the North Hall.

About the Author

Matthew Peach is a contributing editor tooptics.org.